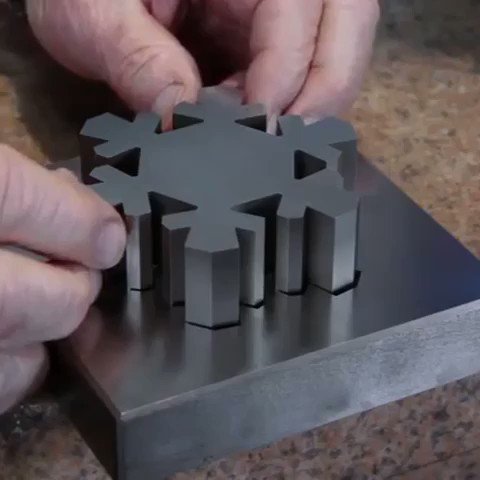

electrical discharge machining puzzle

Modern engineering materials that are deployed in extreme conditions are often shaped or manufactured by EDM process. Electrical discharge machine cannot generate texture background or pebbled patterns these irregular background patterns are usually handmade instead.

Oh Wow Watch A Bunch Metal Shapes Created Using Electrical Discharge Machining Fit Together Seamlessly Dr Wong Emporium Of Tings Web Magazine

The blasts come with extremely high frequency something like 20000 sparks per second along the length of a brass wire.

. Featured items Home Living Tensegrity Structure Floating Table Model 2900 Rated 483 out of 5 Toys Hobbies Titanium Spinning Top 1500. Electrical Discharge Machining Elman C Jameson Career Hang Gliding. In traditional processes metal workpieces are made from special grades of hardenable tool steels machined in an anneal of soft state to facilitate cutting.

The tool is the cathode. Crossposted by 3 years ago. EDM typically works with materials that are electrically conductive although methods have also been proposed for using EDM to machine insulating ceramics.

This is a manufacturing operation in which we used to make desired shapes by using an electrical spark. Here i will be showing you how to make your own EDM machine using simple hand tools and supplies from your local hardware store. Gift and promotional items serving 500 brands sold in 146 countries globally for 35 years.

The suitability of a circuit depends on the machining conditions and requirements. By controlling the gap distance using suitable dielectric medium and delivering a series of voltage pulses between the electrode and workpiece a series of electrical sparks can be generated by pulsing the electrical power input. Known as EDM spark erosion technology Electrical Discharge Machining the manufacturing process solves the kind of machining puzzles that can stymy EDM deprived workshops.

Although the origin of Electrical Discharge Machining EDM goes back to 1770 this technology has rapidly earned its place alongside milling and grinding equipment as a proactive mainstream technology. Electrical discharge machining EDM is a commonly used manufacturing process for creating slots eyelets grooves and cut-offs in processed parts. Controlling machining parameters like discharge duration voltage pulse current the white.

EDM typically works with materials that are electrically conductive although methods have also been proposed for using EDM to machine insulating ceramics. Electrical Discharge Machining is also called or known as Spark machining spark eroding burning die sinking wire burning or wire erosion. The reason behind its rise is the ability of the EDM process to machine complex shapes in very hard metals.

Spark machining uses electrical discharge energy to subtract metal from a workpiece. Wiron Cube The Oddly Satisfying EDM Puzzle Pieces Experience the satisfaction of advanced wire EDM jigsaw puzzle. 64000 square meters production plant and 2000 experienced workers.

Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques. This method is popular because of the fact that EDM can machine any materials irrespective of its hardness. The wire itself never actually touches the material but.

The Wiron Metal Cube creates a mesmerizing seamless effect when assembled. Ask Question Step 1. Edm is the thermal erosion process in which metal is removed by a series of recurring electrical discharges between a cutting tool acting as an electrode and a conductive workpiece in the presence of a dielectric fluid.

Ii Rotary impulse generator. In EDM or electrical discharge machining theyre not physically touching the parttheyre machining with lightning bolts literally sparks. They applied the commonly observed phenomenon of erosion on electrical switch to machining.

Electrical discharge machining EDM is a popular nonconventional machining approach that is often used on hard materials. Iii Controlled pulse circuit. Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques.

I Resistance-capacitance relaxation circuit with a constant dc source. In practical terms electrical discharge machining overcomes a major issue found in contact machining. This discharge occurs in a voltage gap between the electrode and workpiece.

Electrical discharge machining leads to these perfectly fitted steel puzzles. EDM Electrical Discharge Machining Northern Gauge has the capability to wire cut EDM pieces with 400 x 300 mm XY range and with a Z axis range of 250mm. What is electrical discharge machining.

This spark near to 8000 to 12000º C. The process involves an electrical spark being created between a wire and the item being machined. Lets delve deep into the technology the methods the applications and the.

Dear Daniel The thermal energy discharged in machining zone mainly governs the white layer thickness. Much like processes such as laser cutting EDM does not need mechanical force in the removal process. Because EDM does not require high cutting force it creates very low residual stresses making it a powerful tool for manufacturing medical parts.

Tallry The Great Trail An Indian Mystery PlayMarie Elizabeth Jefferys Hobart The MadjanJeff Ravin Elementary Mathematical Astronomy With Examples And Examination PapersGeorge Hartley Bryan Your Daily DoseChris Searle Journal Of A Chess OriginalStephen Gerzadowicz. This is the reason why it is considered non-traditional contrary. What Is EDM Electrical discharge machining is a method of removing metal using an electric sparks similar to a plasma cutter but on a much smaller scale and under water.

Extremely high precision CNC wire cut machine with a finish of 06 µ Ra. Electrical Discharge Machine Sinker EDM Electrical discharge machining or EDM is a non-traditional method in which material is removed from a workpiece using thermal energy. But despite its strengths there are a few key shortcomings of.

Working Principle of Electric Discharge Machining The workpiece and the tool are electrically connected to dc electric power. The commonly-used principles for supplying the pulsating dc can be classified into the following three groups. A gap known as the spark-gap in the ranges of 0005 to 005 mm is maintained between the workpiece and the tool.

The workpiece is connected to the ve terminal it becomes the anode. Heat from the discharge vaporizes minute particles. Electrical discharge machining leads to.

This is how an electro-discharge machine looks like.

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Fabrication Vacuum Technology Inc

Electrical Discharge Machining Leads To These Perfectly Fitted Steel Puzzles R Engineeringporn

Electrical Discharge Machining Leads To These Perfectly Fitted Steel Puzzles R Engineeringporn

World Of Engineering On Twitter Amazing Accuracy Of Electrical Discharge Machining Wire Edm Can Cut With Accuracies Of 0001 00254 Mm Worldofengineering Engineering Technology Edm Machining Source Reliableedm Youtube Https T Co

Amazing Cube And Sphere Made By Wire Cut Edm Machine Youtube

High Quality Wire Cut Edm Wire Cutting 25mm 25mm Skd11 Steel Puzzle Parts Milling High Polished Buy Wire Cut Edm Edm Wire Wire Edm Wire Product On Alibaba Com

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Magic Cube Finally I Could Do One Myself R Machinists

Mitsubishi Wire Edm Puzzle Pieces Youtube

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

The Precision Of Wire Edm R Oddlysatisfying

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Zero Tolerance Machining With The Wire Edm Making A Puzzle Cube Part 2 Us Digital Youtube

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired